Areas of innovative activities

Sovcomflot Group’s innovative activities are carried out in accordance with the requirements and methodological guidelines of the Federal Agency for State Property Management (Rosimushchestvo), the Russian Ministry of Economic Development and the Council for Economic Modernisation and Innovative Development under the President of the Russian Federation. Priority directions for innovative development of the Group are determined in accordance with Decree No. 899 of the President of the Russian Federation dated 7 July 2011.

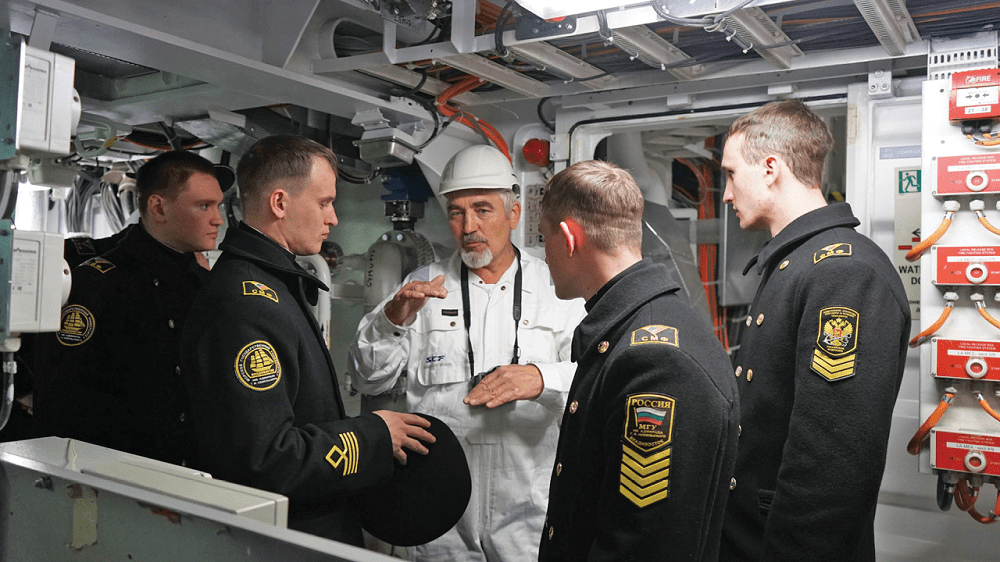

Sovcomflot is developing its own engineering school. SCF’s engineering, operations and training centres have been integrated at the St. Petersburg headquarters, creating a unique blend of knowledge and practical experience accumulated by the company and giving an additional impulse to the development of unique industrial projects with an ice component.

The main areas of innovative activities and scientific, R&D and technological projects of Sovcomflot Group in 2019 were as follows:

- Exploring opportunities for improving energy efficiency and reducing carbon, sulphur and nitrogen oxides emissions:

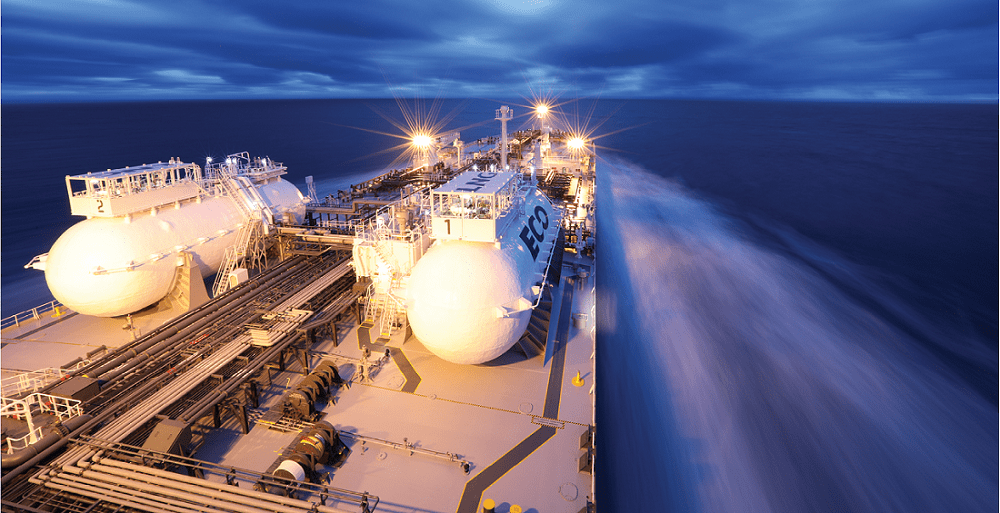

- using a boil-off gas reliquefaction system to return boil-off gas to the cargo tanks or use it as a fuel for the ship power plant on gas carriers (implemented as part of the construction of the LNG carrier SCF La Perouse added to the fleet in February 2020);

- a hull air lubrication system to reduce the resistance and increase the speed of the ship for SCF La Perouse-class LNG carriers (not implemented at this stage, is being considered in the context of future projects);

- fitting rotor sails to LNG-fuelled Aframax vessels (not implemented at this stage, is being considered in the context of future projects).

- Working on projects for new types of LNG-fuelled vessels - a VLCC tanker, an offshore platform supply vessel, an icebreaker.

- Participating in the development of automated and remote control technologies for large-capacity commercial vessels, which involves creating and validating technical tools and drafting requirements to be incorporated into Russian and international legal and tech-nical regulations that create conditions for operating unmanned vessels. As at the end of the reporting period SCF Group masters were participating, as part of an expert council, in preparations for the first stage of pilot operation, which includes the development of the basic automated and remote control algorithms and their testing on shore test-bed based on the array of data received from vessels.

- Participating in the DecarbonICE project initiated by Maritime Development Center, a non-profit environmental research organisation. The company is exploring opportunities for employing the proposed technology, which allows using existing marine fuels while significantly reducing carbon dioxide generation.

- Conducting research, calculations and experiments to select optimal parameters for ship power plants in terms of compliance with conventional requirements.

- In the reporting period company experts carried out work at the SCF training centre in St. Petersburg to determine the conditions for safe navigation within the sea channel of the Gulf of Ob by modelling the movement of a gas carrier in waters covered with ice of various thickness and a counter movement of two vessels in the channel on a navigation simulator. Also, recommendations and regulations concerning navigation in the sea channel of the Gulf of Ob were developed. As a result, the Russian Ministry of Transport made a decision to reconstruct the sea channel.

- Employees from the SCF training centre took part in the research work on the topic «Development of regulations for bunkering ships with liquefied natural gas», which involves the development of national level standards that set uniform requirements for all participants in the open market for LNG bunkering services.

- The Sovcomflot Group’s Green Charter - a declaration of commitments to fight climate change by using innovative technologies and raising personnel awareness on environmental protection (for more details see section 6.4.1. Environmental protection policy) - was approved in March 2019.

Sovcomflot stimulates professional development among its staff and encourages employees to pursue additional education in order to gain in-depth knowledge of modern technologies in fleet management. SCF’s engineering staff have very high scientific capabilities: currently, 33 seafarers, who completed post-graduate studies and received the title of Candidate of Technical Sciences or are preparing to defend their theses, work in the Company’s fleet.

The functional capabilities of the operations centre for real-time vessel tracking, which was opened at the Sovcomflot headquarters in St. Petersburg a year earlier, were expanded during 2019. In particular, SCF specialists developed and launched Ice Observer, a mobile application that simplified and systematised data collection from ships regarding ice conditions, and also digitised the database of ice observations carried out on SCF ships while serving the Prirazlomnoye, Varandey and Novy Port projects. The database is used to teach artificial intelligence systems used for mapping ice conditions, plotting the safest and most optimal route in ice, looking for dangerous ice formations and identifying areas with complex ice conditions.

The centre’s equipment allows for the following tasks to be performed using artificial intelligence:

- Controlling and analysing navigation safety data;

- Optimising ship routes taking into account ice conditions, weather conditions, and business objectives;

- Monitoring the ship’s operation in real time (collecting and processing the ship’s navigation and technical performance parameters, video feeds from surveillance cameras);

- Special Arctic navigation control capabilities: analysis of ice conditions and movements of ships, identification of dangerous ice formations and areas with complex ice conditions, development of recommendations for masters and determination of the safest route in ice conditions;

- Control and analysis of the performance of the ship’s systems in terms of energy efficiency, bunker consumption, etc.;

- Remote access to the ship’s systems, log of faults, etc. for onshore specialists to analyse the technical condition of the ship in case of malfunctions in ship systems and help crews to fix faults.

Key achievements in innovation and R&D

- Sovcomflot Group won the award for ‘Company of the Year’ at the 2019 Lloyd’s List Europe Awards. In particular, the jury noted the successful implementation of technologies for using cleaner LNG fuel for large-capacity tankers, inauguration of a state-of-the-art operations centre and industry-leading safety record, which comes despite operating in some of the worlds’ harshest conditions.

- The Gagarin Prospect tanker was named ‘Ship of the Year’ at the Marine Propulsion Awards 2019. Also, the vessel won the Next Generation Ship Award 2019. Gagarin Prospect is the lead ship in the ‘Green Funnel’ series of Aframax crude oil tankers using LNG as the primary fuel. As at 31 December 2019 the SCF Group fleet included six tankers running on LNG. The results of the first year of operation of the series showed that the use of LNG allows for a 30% reduction in carbon dioxide emissions compared to similar vessels that run on conventional heavy fuel.

- Gagarin Prospect and Lomonosov Prospect received Green Award certificates, a quality mark for vessels that significantly surpass convention requirements related to navigation safety and environmental protection.

- Yevgeny Primakov, a multifunctional icebreaking platform supply vessel, was named Support Vessel of the Year by Offshore Support Journal, an international trade publication. The vessel was accepted for operation in 2018 and is employed to support offshore oil and gas platforms of the Sakhalin-2 project on the continental shelf of the Sea of Okhotsk and Sakhalin Island under a long-term agreement with Sakhalin Energy.

- A new edition of a unique training manual, Practical Recommendations by SCF Captains for Steering Vessels in Ice Conditions, was published in January 2019. The author team is comprised of ice captains of Sovcomflot ships that participated in the implementation of Arctic industrial projects. The manual is based on the consolidated and systematised experience gained on the Sakhalin-1, Varandey, Prirazlomnoye and Novy Port projects. In the new edition, practical recommendations on the use of Azipod propulsion units to manoeuvre Arctic shuttle tankers were complemented by experience in using them in heavy ice conditions in the Kara Sea and the Gulf of Ob.

- During the reporting period, work was also undertaken to prepare a new training manual, Practical Recommendations for Steering a Vessel with three Azipod Propulsion Units in Ice Conditions in Relation to the Yamal LNG Project, which summarizes the experience in steering icebreaking vessels with a powerful power plant accumulated in the Yamal LNG project. Special attention was paid to navigation in the most difficult area - the outlet of the Ob River to the Kara Sea, where large-capacity vessels have to sail along the long and narrow Sea Channel in conditions of constant ice drift. The new manual is expected to be published in 2020.

- During the reporting period Sovcomflot continued to consistently introduce cargo transportation by large-capacity tankers using LNG fuel in Arctic navigation. During the 2019 summer navigation period the company’s three LNG-fuelled tankers completed eastbound voyages along the high-latitude Northern Sea Route and one tanker from the ‘Green Funnel’ series sailed through this route in the western direction.

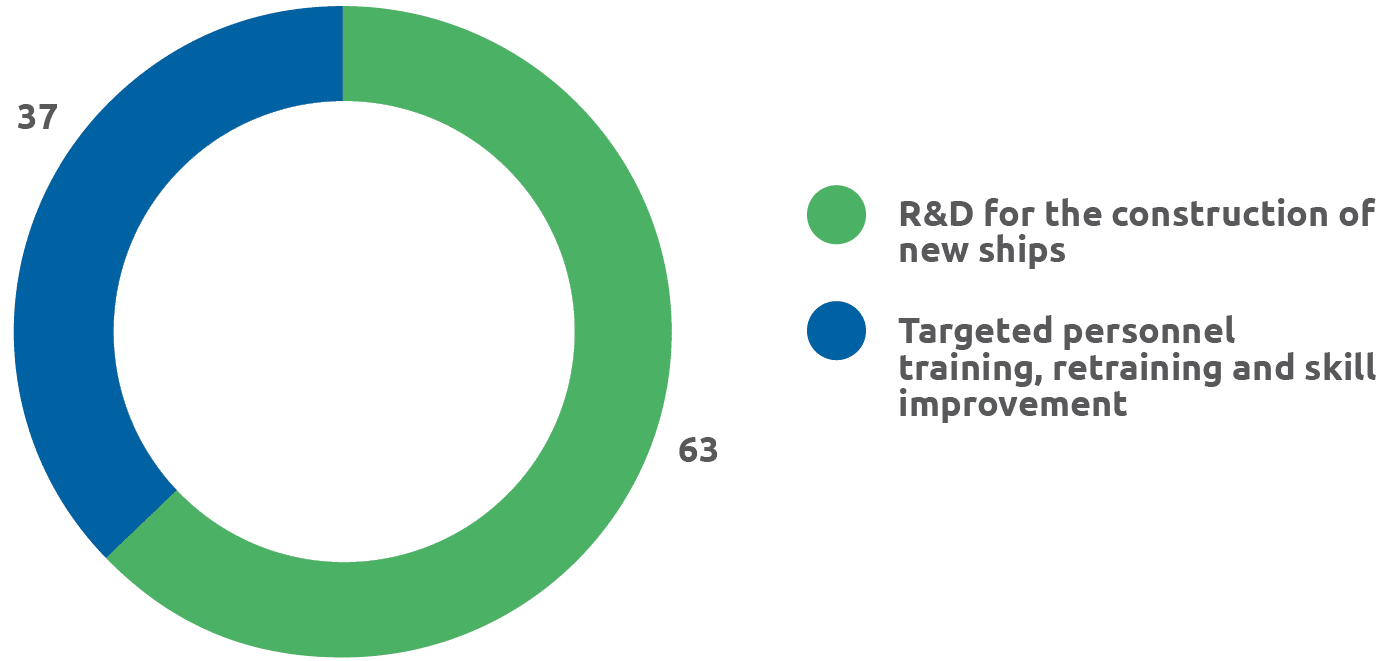

Financing of innovative activities

The financing of R&D, engineering activities, professional training, retraining and skill improvement of PAO Sovcomflot personnel in 2019 amounted to US$4.7 million.